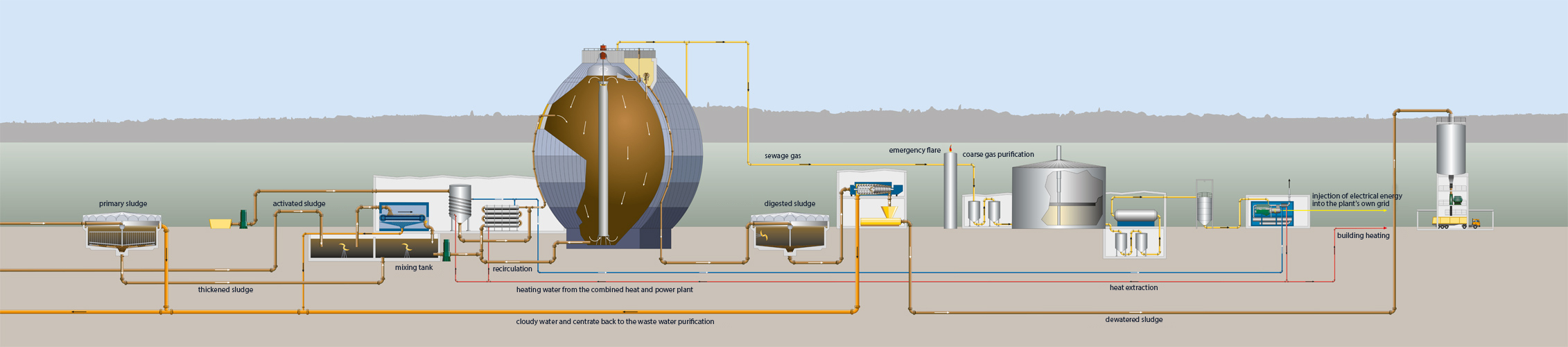

First, the sludge must be thickened. The primary sludge from the mechanical pre-treatment rests in round tanks for about two days. Due to gravity, the sludge compacts at the bottom. Above it, a layer of cloudy water forms. This water is pumped back into the wastewater treatment process. During thickening, the primary sludge loses about two-thirds of its volume.

- Amount of primary sludge: 1,600 m³ / day

- Diameter of the 3 tanks: 18 meters each, depth approximately 5 meters

- Dry matter content: before 2%, after 6%

The activated sludge from the biological wastewater treatment (excess sludge) is distributed on a sieve belt. During the approximately two-meter-long journey, water trickles through millions of tiny holes, like in a coffee filter. The sludge flocs remain on the belt. Afterward, the sludge has lost 90% of its liquid.

- Amount of activated sludge: 4,200 m³ / day

- 4 belt thickeners

- Dry matter content: before 0.5 - 1%, after 5 - 7%

The thickened primary and excess sludge is mixed and heated to about 37°C before being fed into the towers. This is the optimal temperature for methane gas production. The required heat comes from the cogeneration plant (CHP).

To maintain the temperature in the digesters, sludge is continuously extracted and recirculated through the heat exchanger (recirculated sludge).

- Inlet temperature of the heating water from the CHP: approximately 85°C

- Ratio between fresh and recirculated sludge: approximately 1:5

In the towers, the sludge is digested (or fermented) with the help of bacteria. Almost half of its organic content is converted into biogas. The gas rises to the top of the digester – the gas dome – and is then extracted.

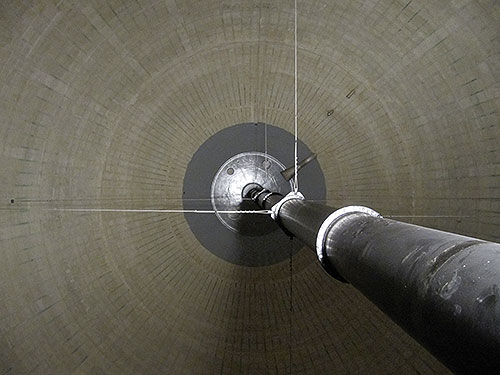

An agitator draws the sludge through a vertical mixing pipe and keeps it in motion. This ensures good temperature distribution and prevents deposits. The shape of the towers, resembling eggs, also serves this purpose.

- Height: 35 meters, width: 26.5 meters.

- Volume: 2 x 10,500 m³

- Operating temperature: 37°C

- Digestion time: approximately 18 - 20 days

- Fresh sludge: 1,000 m³ / day

- Gas yield: 15,000 m³ / day

The digested sludge is further dewatered in centrifuges. The principle is similar to that of a spin dryer. The sludge now has the consistency of moist soil (experts say it is firm).

- Output: 25% dry matter

- Rotations: 1,500 / min

- Drive power: 110 kW

In the gasometer (5,000 m³), gas is temporarily stored to ensure continuous operation of the cogeneration plant during fluctuations.

gas cleaning - The main targets here are hydrogen sulfide and the so-called siloxanes. The latter could form sand (silicon dioxide) in the combustion chamber of the gas engine, causing wear on the engine. Activated carbon and ceramic filters are used for this purpose.

gas drying - Biogas contains water vapor. To increase the efficiency of the gas engine, the moisture must be removed from the gas. This is done by lowering the temperature (condensation).

gas compression - For fine cleaning and subsequent feeding into the gas engines, the gas pressure is increased using compressors.

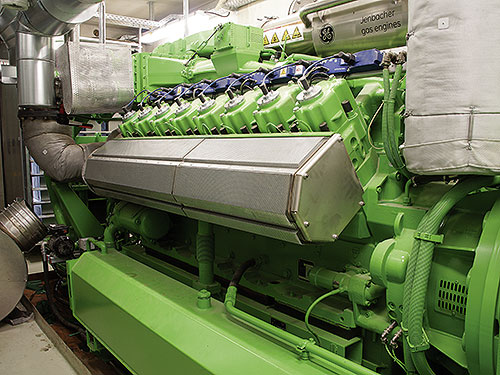

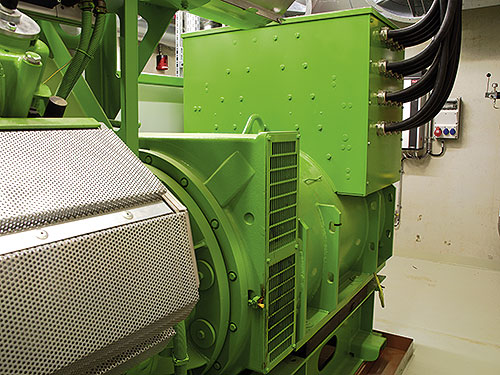

Three engines, powered by purified biogas (65 percent methane), each drive a generator. The generated electrical energy is fed into the wastewater treatment plant's grid. The heat produced is used to warm the sludge and heat the operational buildings.

- Gas engines: 2x 1,100 kW electrical power each, 1x 835 kW electrical power

- 16-cylinder V engines (Otto)

- Annually generated energy: Electricity: 17,000 MWh, Heat: 16,000 MWh

From the centrifuges, the dewatered sewage sludge goes into the silos of the loading station. There, trucks are filled, which take it to agricultural enterprises or composting facilities (in 2013, the ratio was about 50/50).

- 150 tons per day

- Consistency: firm soil or fresh mortar

- 6 trucks (each 25 tons) per day